In order to reduce the technical and economic risks, specific R&D challenges are expected to be resolved by carrying out experimental activities on a scaled version of the multi-purpose platform (outdoor scaled prototype) to be installed on sea at Natural Ocean Engineering Laboratory (NOEL) test site in Reggio Calabria, Italy.

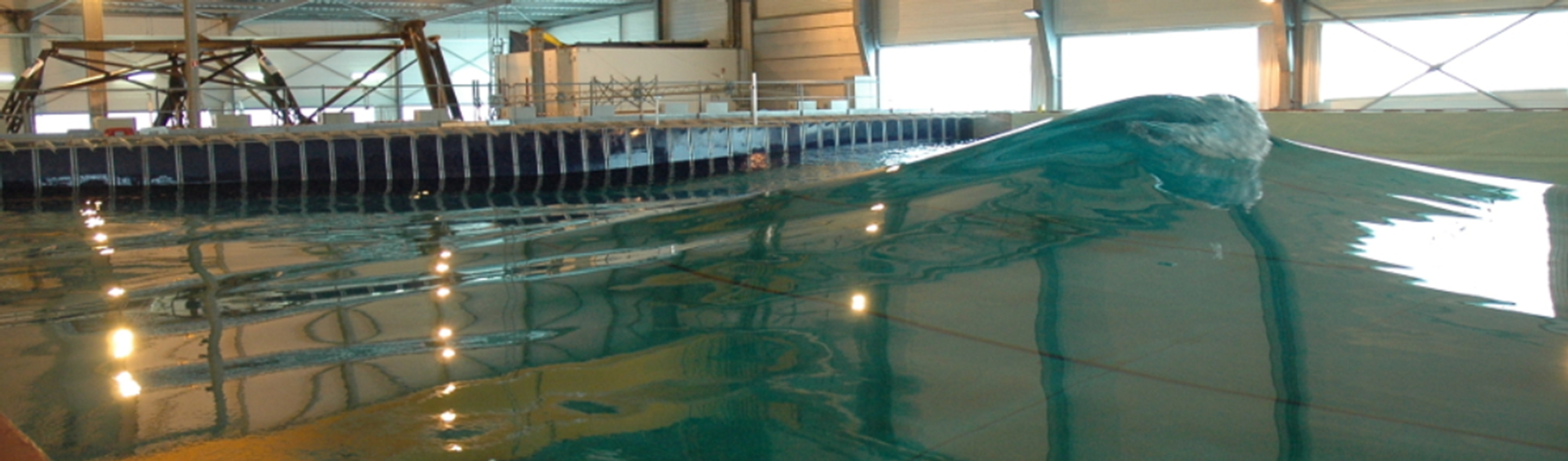

Suitable input to the outdoor prototype and full-scale design phases will be given by experimental validation of the coupled dynamics to be carried out through an indoor scaled prototype to be tested at the Ocean Basin wave tank, Nantes Laboratory.

In addition, an early activity specifically addressed at evaluating the impact on the fish of the close co-location of the aquaculture system with other systems of the multi-purpose platform is to be carried out by Strathclyde University with the use of literature surveys, numerical models and experimental investigation.

The reduced scale physical platform prototypes will be designed in parallel with the full-scale platform so that they can be fitted with the essential items and systems required in order to validate design concepts and enable the achievement of various levels of the qualification process.

The indoor prototype of the Blue Growth Farm will be manufactured at Centrale Nantes (FR) and directly tested in their wave tank facilities.

The outdoor prototype of the Blue Growth Farm will be manufactured in Ancona (IT), and then transported by sea in the Port of Reggio Calabria (IT) for an intermediate step of technologies integration. After that, it will move on sea to its final installation site, in the sea public area under concession of the Natural Ocean Engineering Laboratory (NOEL) in Reggio Calabria.

Whilst the indoor prototype is planned to provide preliminary insight about platform stability, interaction of wind turbine and WECs on the platform dynamics, overall influence of nets on drag forces, the outdoor experimental R&D campaign is expected to show elements of validation of the following design challenges:

- buoyancy of the selected platform shape configuration: analysis of measurement data from meteocean sensors;

- stability and dynamics of the platform fitted with the renewable energy production systems under real wind and wave loadings: combined analysis of data coming from sensors on wind turbine tower and on platform;

- interaction between the rigid platform and the aquaculture cages: visual inspection of nets movement and interaction with other subsea components, analysis of data coming from sensors within the pool, and from load cells located at the mooring lines;

- structural resistance of steel caisson connections under sea wind and wave loading: analysis of data from SHM;

- behaviour and loading effects on the mooring system: analysis of data from sensors placed at mooring chains level;

- behaviour and loading effects on the umbilical dynamic cable: analysis of data from sensors placed at cable/connector level;

- interaction of the mooring system with the umbilical cable: analysis of optical data (camera), data from sensors placed at mooring chains / cable / connector levels, and direct in situ inspection;

- testing of device-to-cable connection: proof of effective manoeuvring during connection & disconnection operations, structural resistance, water-tightness and umbilical cable integrity (testing carried out with umbilical cables electrically disconnected from the generator).

- testing of the surveillance and security system (offshore camera) and machine learning based control system.